Smart Factory IoT Platform

The Challenge

Production lines ran on legacy PLCs with no unified visibility. Maintenance was reactive, energy costs were surging, and leadership lacked real-time metrics to make decisions.

Our Solution

We deployed edge gateways with secure MQTT connectivity, built a streaming ingestion pipeline, and layered digital twins plus alerting dashboards. Predictive models flag anomalies hours before breakdowns.

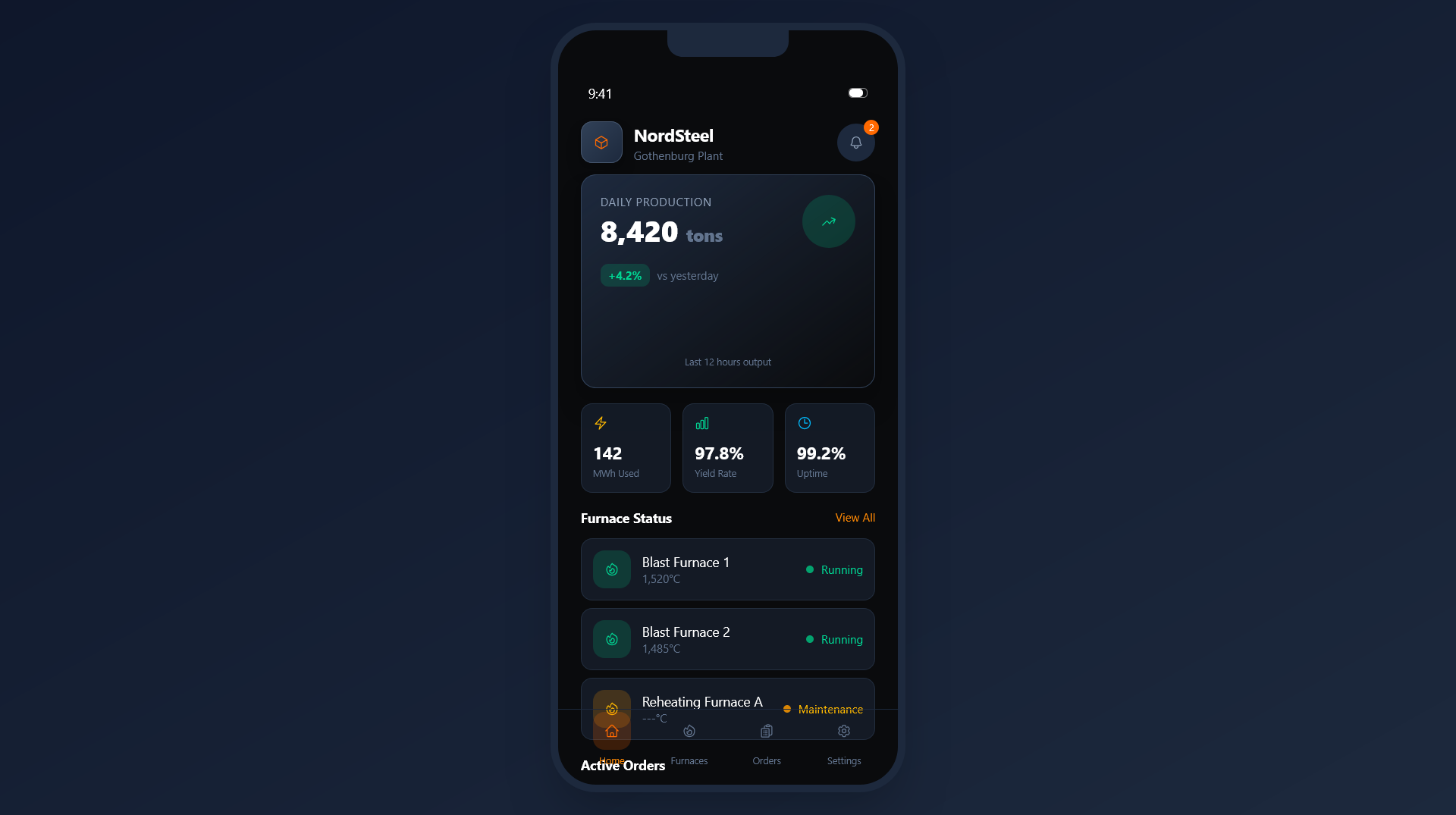

Key Features Delivered

- Edge anomaly detection with on-device inference

- Digital twins for each production cell

- Role-based dashboards for maintenance, ops, and leadership

- Automated work orders via ServiceNow integration

- Carbon and energy tracking by line and facility

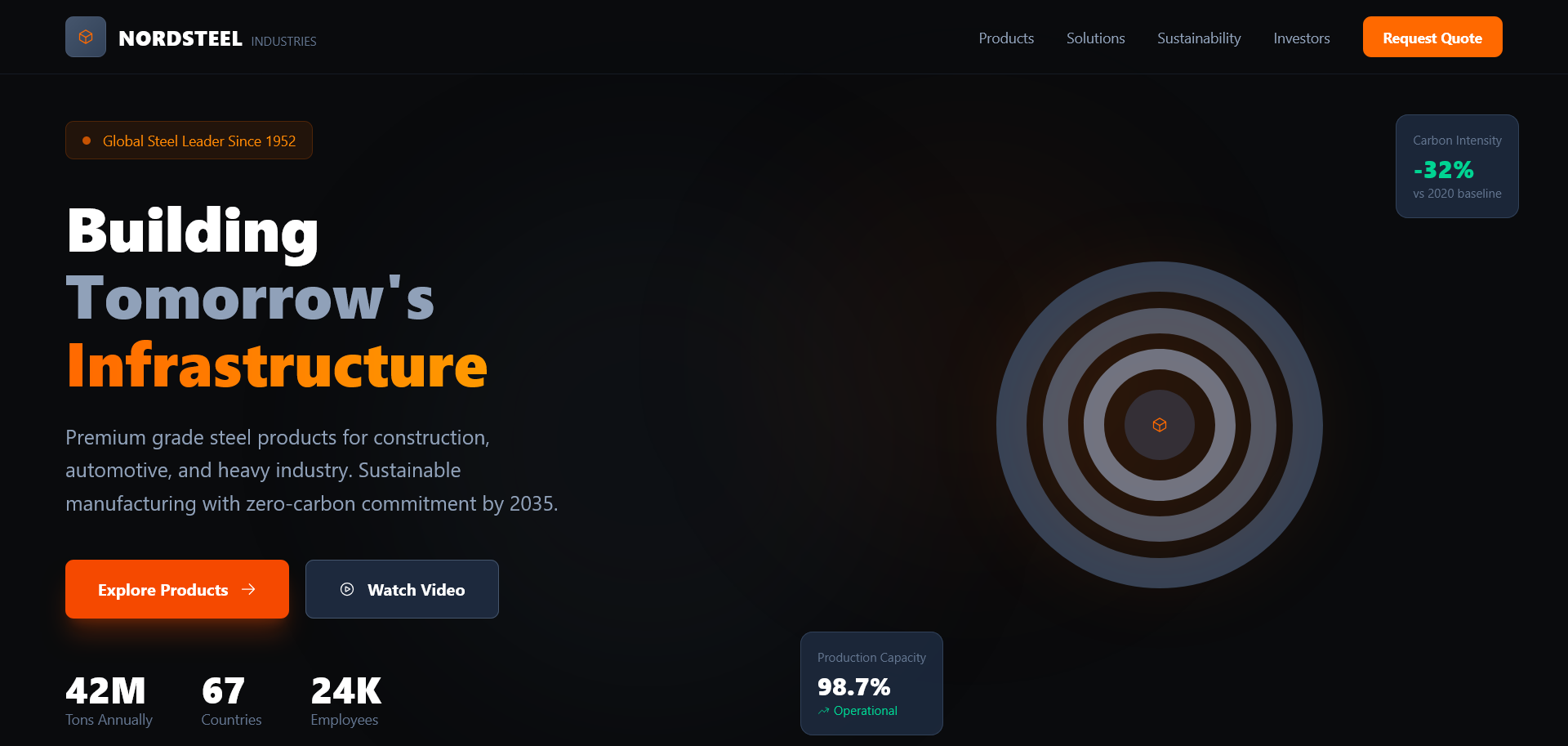

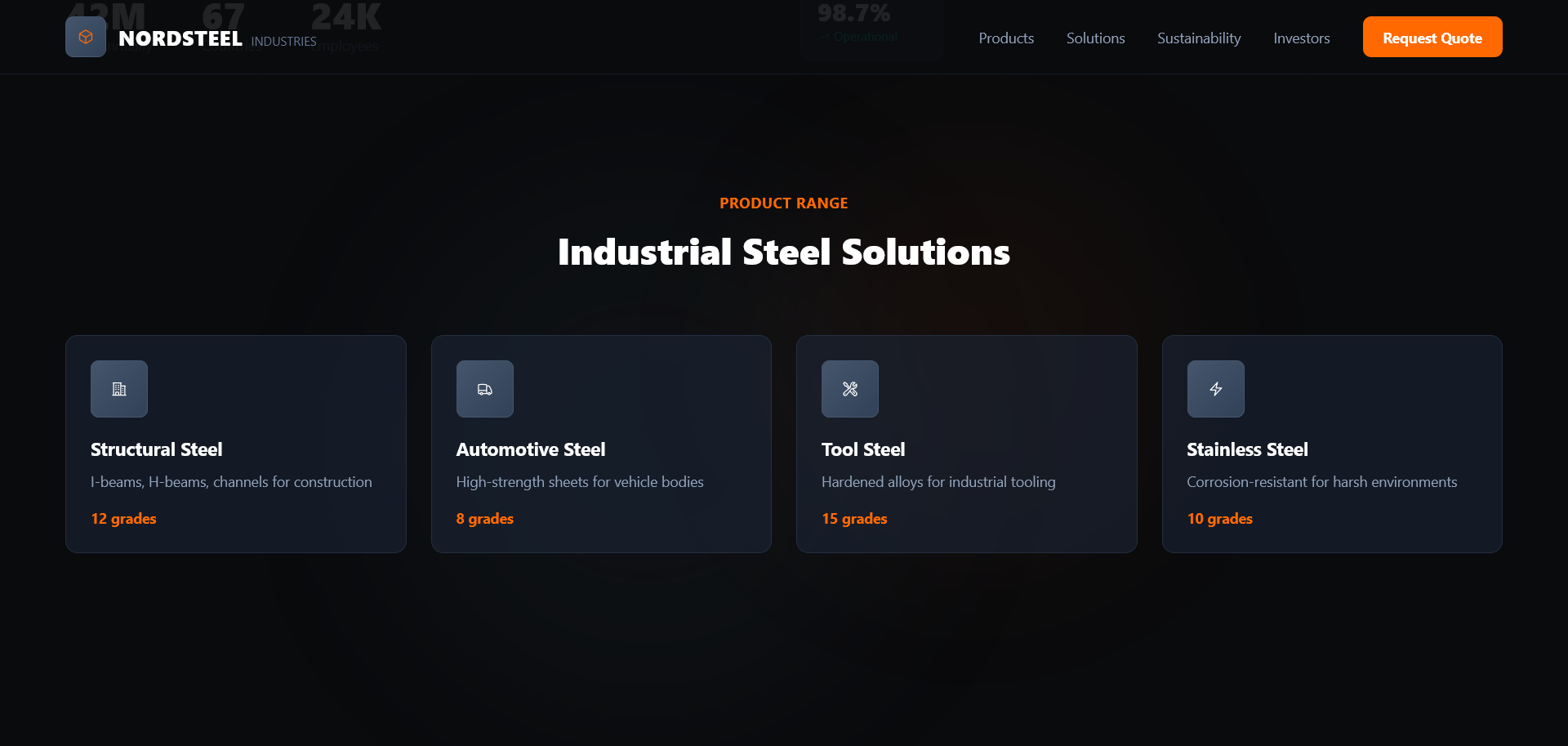

Project Gallery

Explore the project visuals

Technology Stack

Powered by industry-leading technologies

Business Impact

Maintenance teams now intervene before failures, saving $4.1M annually. Operators monitor OEE in real time, and the sustainability team hit energy reduction targets ahead of schedule.

Project Timeline

Sensor & PLC Audit

3 weeks

Catalogued equipment, communication protocols, and data availability across plants.

Pilot Line Deployment

5 weeks

Installed edge gateways, built ingestion and alerting for a single production line.

Platform Scale-Out

8 weeks

Rolled out across all lines with automated device provisioning and SSO integration.

Optimisation & Training

4 weeks

Ran workshops, tuned models, and launched executive dashboards.

"We finally have one source of truth for operations. The predictive alerts alone paid for the project in six months."

Ready to Transform Your Business?

Let's discuss how we can help you achieve similar results

Trusted By Industry Leaders

Proven Track Record of Excellence

Delivering AI-powered solutions to enterprises worldwide with measurable ROI and lasting impact